The Final Design Process

- Annamae Muldowney

- Jan 14, 2022

- 1 min read

Success at Last

My first successful test model was a combination of a stack method and a waffling method. This combination helped refine the inner form but the pieces were two thick. This thickness making the model too expensive and heavy to construct.

Cladding

To Combat this I came up with a cladding solution. Instead of one heavy piece, this piece would now be made up of two thin layers with lino filling the gap between.

Outer cavities

These spaces were unusual forms, I brainstormed how the space around this structure might be used when retrofitted into standard rooms, I was interested in how this could form a service cavity. I began to test this with light in my model.

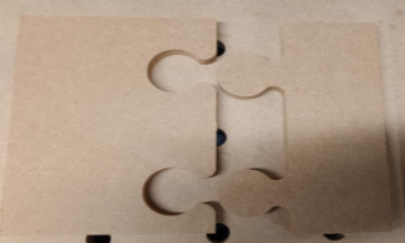

Joining elements

The CNC cutter in Linenhall has a limited bed size of 1200 x 600 mm, this meant any large pieces would need to be cut in segments and joined together. I tested difference joins to find the best method, what I learned here was the importance of tolerances.

Comments